Enhancing Efficiency: The Definitive Guide to Shaft Mounted Reducers in Power Transmission

Enhancing Efficiency: The Definitive Guide to Shaft Mounted Reducers in Power Transmission Table of Contents 1. Introduction to Shaft Mounted Reducers 2. What Are Shaft Mounted Reducers? 3. Key Benefits of Shaft Mounted Reducers 3.1 Enhanced Operational Efficiency 3.2 Space-Saving Design 3.3 Mechanical Simplicity 4. Applic

1. Introduction to Shaft Mounted Reducers

In today's rapidly evolving industrial landscape, the importance of efficiency in power transmission cannot be overstated. Shaft mounted reducers play a crucial role in enhancing system performance, ensuring that machines operate smoothly and effectively. By understanding the mechanics and benefits of these components, we can harness their full potential for improving productivity and reliability across various applications.

2. What Are Shaft Mounted Reducers?

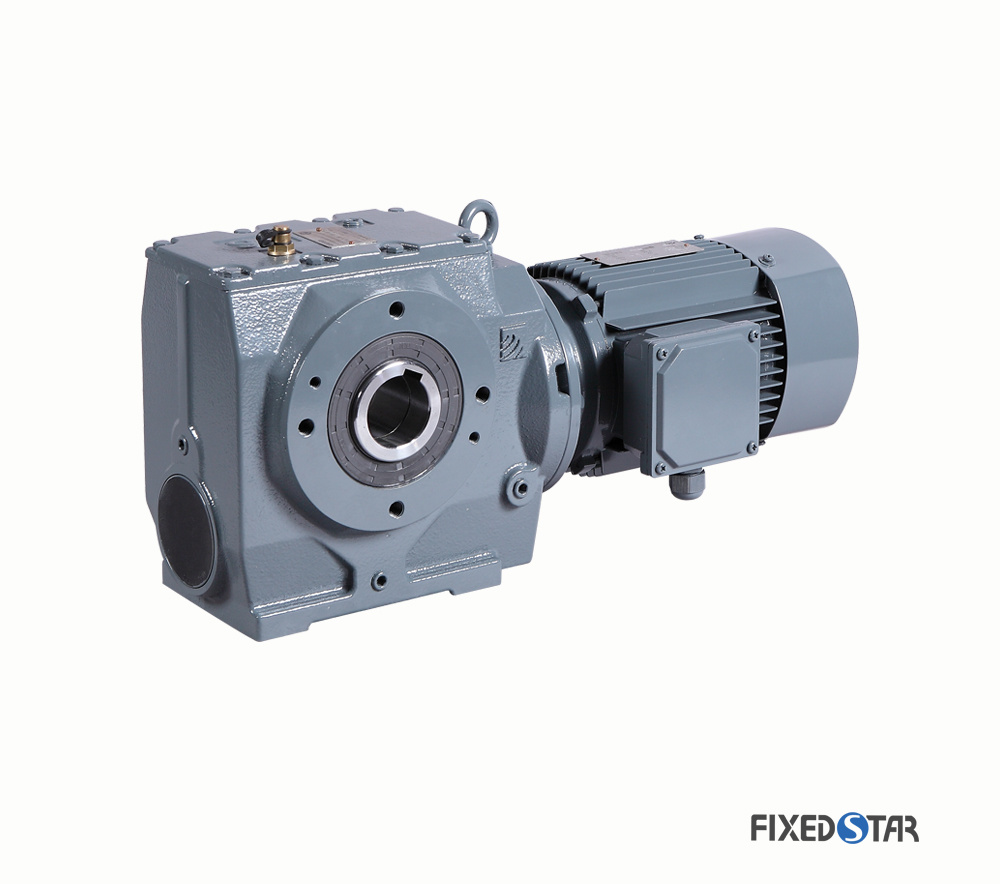

Shaft mounted reducers are mechanical devices designed to reduce the speed of an input drive while increasing torque output. Typically mounted directly onto the shaft of an electric motor, they provide a compact solution for achieving desired performance characteristics in power transmission systems. Their design often includes a gear system that allows for seamless power transfer, minimizing losses and maximizing efficiency.

3. Key Benefits of Shaft Mounted Reducers

3.1 Enhanced Operational Efficiency

One of the primary advantages of shaft mounted reducers is their ability to significantly enhance operational efficiency. By reducing the speed of the input shaft, these devices help maintain optimal motor performance and conserve energy. This not only leads to lower operational costs but also reduces wear and tear on machinery, extending the lifespan of equipment.

3.2 Space-Saving Design

In industries where space is a premium, shaft mounted reducers offer a unique advantage. Their compact design allows them to fit within limited spaces without compromising functionality. This space-saving feature is particularly beneficial in manufacturing environments where equipment layout can affect overall efficiency.

3.3 Mechanical Simplicity

Shaft mounted reducers are known for their mechanical simplicity, which translates to easier installation and maintenance. Unlike traditional gear systems that may require complex setups, these reducers can be mounted directly on the motor shaft with minimal additional components. This simplicity not only reduces installation time but also lowers the risk of mechanical failure.

4. Applications of Shaft Mounted Reducers

4.1 Industrial Applications

Shaft mounted reducers find extensive application in a variety of industrial sectors. From conveyor systems to processing machinery, their ability to deliver consistent torque and speed control makes them invaluable in manufacturing and assembly lines. Industries such as automotive, textiles, and food processing rely on these devices to enhance productivity and maintain operational flow.

4.2 Agricultural Applications

In agriculture, shaft mounted reducers play a vital role in equipment such as tractors, harvesters, and irrigation systems. By providing the necessary torque to drive various attachments, these reducers ensure that agricultural machinery operates efficiently, even under heavy loads. This efficiency translates to improved productivity for farmers and reduced operational costs.

5. Choosing the Right Shaft Mounted Reducer

Selecting the appropriate shaft mounted reducer for your application involves several considerations. We must evaluate factors such as load requirements, speed reduction ratios, and environmental conditions. Understanding the specific needs of your machinery will help in choosing a reducer that optimally matches your requirements, ensuring peak performance and efficiency.

6. Maintenance of Shaft Mounted Reducers

Maintaining shaft mounted reducers is critical for ensuring their longevity and performance. Regular inspections should focus on checking lubrication levels, tightening bolts, and monitoring for signs of wear or damage. Prompt attention to these areas can prevent costly downtime and maintain the efficiency of your power transmission system.

7. The Future of Shaft Mounted Reducers in Power Transmission

As industries continue to evolve, shaft mounted reducers are likely to incorporate more advanced technologies. Innovations such as smart sensors and automated monitoring systems are expected to enhance the operational capabilities of these devices. The future will likely see an ongoing trend towards greater efficiency, reduced energy consumption, and improved integration with digital systems in power transmission applications.

8. FAQs About Shaft Mounted Reducers

1. What is the primary function of a shaft mounted reducer?

The primary function of a shaft mounted reducer is to reduce the input speed from a motor while increasing the output torque, enhancing the efficiency of power transmission systems.

2. How do I determine the correct size of a shaft mounted reducer for my application?

To determine the correct size, consider the load capacity required, the speed reduction ratio you need, and the specific operational conditions of your machinery.

3. Are shaft mounted reducers suitable for outdoor applications?

Yes, shaft mounted reducers can be designed for outdoor applications, but it is essential to select units that are specifically rated for environmental conditions such as moisture, temperature, and dust.

4. How often should shaft mounted reducers be maintained?

Maintenance frequency can vary depending on usage conditions, but it is generally recommended to inspect and maintain shaft mounted reducers every six months to ensure optimal performance.

5. Can shaft mounted reducers be used in tandem with other power transmission components?

Absolutely! Shaft mounted reducers can be effectively used in conjunction with other components such as belts, chains, and couplings to create a comprehensive power transmission solution.

Conclusion

Shaft mounted reducers are integral to enhancing efficiency in power transmission systems. Their numerous benefits, including improved operational efficiency, compact design, and mechanical simplicity, make them indispensable in various industrial and agricultural applications. By understanding their functionalities and applications, we can better leverage these devices to streamline processes, reduce costs, and improve overall performance in our operations. As technology continues to advance, the future of shaft mounted reducers holds exciting possibilities for better integration and efficiency in power transmission systems.

Related news