Transforming Electrical Systems: The Evolution of Double Stage Gear Drives

Transforming Electrical Systems: The Evolution of Double Stage Gear Drives Table of Contents 1. Introduction to Double Stage Gear Drives 2. Historical Evolution of Gear Drives 3. Mechanical Principles of Double Stage Gear Drives 4. Key Advantages of Using Double Stage Gear Drives 5. Applications of Double Stage Gear Drives in Industries 6. Innovations in Gear Drive Technol

1. Introduction to Double Stage Gear Drives

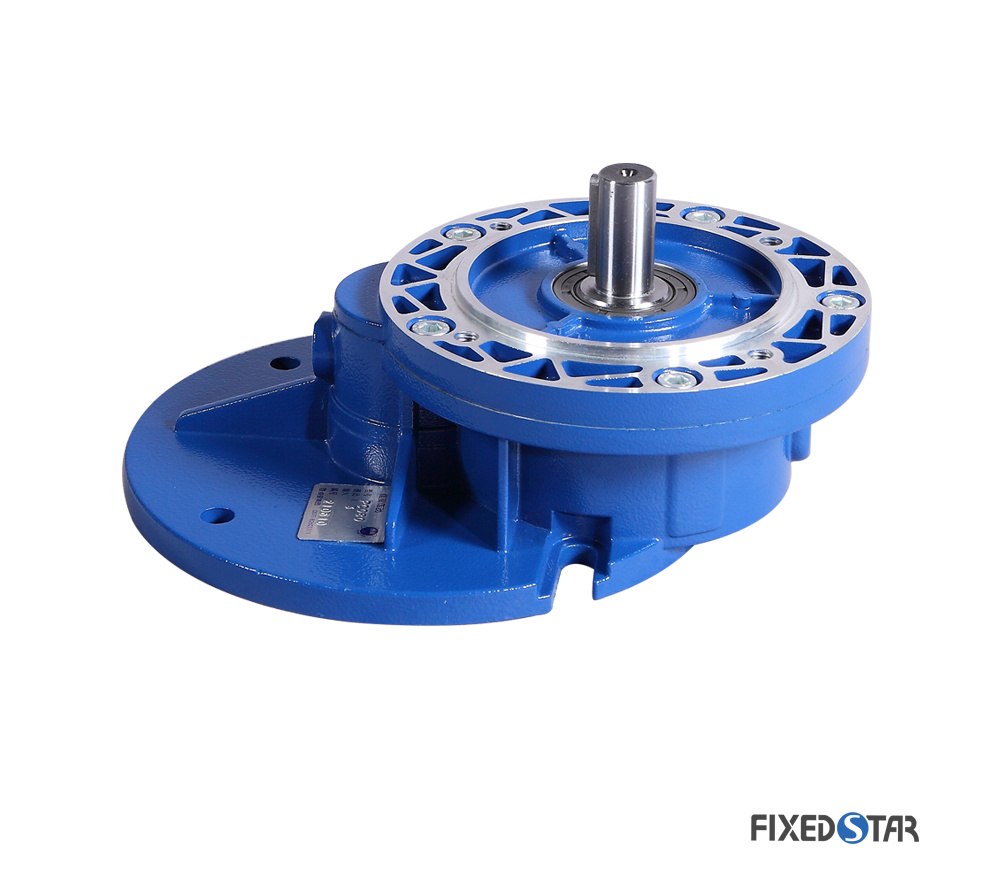

Double stage gear drives are pivotal components in modern electrical systems, playing a vital role in energy transmission and mechanical power efficiency. By utilizing a two-stage reduction process, these drive systems convert high-speed, low-torque input into low-speed, high-torque output. This transformation is essential in various applications, from industrial machinery to automotive systems, where performance and reliability are paramount.

The importance of double stage gear drives cannot be overstated. They provide crucial advantages in torque multiplication and speed reduction, making them indispensable in numerous industries. As we explore the evolution and mechanics behind these systems, we will uncover how they have transformed electrical systems and what the future holds for this technology.

2. Historical Evolution of Gear Drives

The concept of gear drives dates back centuries, evolving from simple mechanical systems to complex technologies that power modern machines. Early gear mechanisms were made from wood and metal, serving basic functions in mills and simple machinery. However, as industrialization progressed, so did the need for more efficient power transmission methods.

The introduction of double stage gear drives marked a significant advancement in the field. Initially, these systems were utilized in heavy machinery, such as cranes and hoists, to manage substantial loads. Over time, advancements in materials and manufacturing techniques led to the development of precision gear drives capable of delivering higher performance.

In recent decades, with the boom in automation and robotics, double stage gear drives have become integral to various sectors, including manufacturing, transportation, and renewable energy. This evolution reflects not only technological advancements but also the increasing demand for efficiency and sustainability in electrical systems.

3. Mechanical Principles of Double Stage Gear Drives

At the core of double stage gear drives lies a sophisticated mechanical design that ensures optimal performance. The system consists of two sets of gears, typically arranged in a series configuration. The first stage reduces the speed from the input motor, while the second stage further reduces the speed and increases torque.

This two-stage process allows for greater flexibility in selecting gear ratios, enabling engineers to tailor the system to specific applications. The mechanical principles governing these drives include:

3.1 Gear Ratio

The gear ratio is a critical parameter that determines the output speed and torque. In a double stage gear drive, the overall gear ratio is the product of the individual ratios of both stages. For instance, if the first stage has a ratio of 4:1 and the second stage has a ratio of 2:1, the total gear ratio will be 8:1. This means that for every eight rotations of the input gear, the output gear will complete one rotation, significantly increasing torque.

3.2 Efficiency

Efficiency is another vital aspect of double stage gear drives. High-quality materials and precise manufacturing processes minimize energy losses due to friction and heat generation. A well-designed gear drive can achieve efficiency levels of over 90%, making them an attractive choice for energy-conscious applications.

3.3 Load Capacity

The load capacity of a double stage gear drive is influenced by the materials used and the design of the gears. The choice of materials, such as hardened steel or composites, enhances durability and load-bearing capabilities, ensuring that the system can handle the demands of various applications.

4. Key Advantages of Using Double Stage Gear Drives

The adoption of double stage gear drives offers numerous advantages:

4.1 Enhanced Torque Output

One of the primary benefits of double stage gear drives is their ability to generate higher torque output compared to single-stage systems. This feature is crucial in applications requiring substantial lifting or moving of heavy loads.

4.2 Improved Speed Control

Double stage gear drives provide better speed control across a wide range of operating conditions. This flexibility is essential for applications that require precise movement and positioning.

4.3 Compact Design

Despite their enhanced capabilities, double stage gear drives can be designed to be compact and lightweight. This makes them ideal for integration into systems where space is limited, such as in robotics and automated machinery.

4.4 Reduced Wear and Tear

The two-stage reduction results in lower rotational speeds at the output, which reduces wear and tear on components. This longevity is a significant advantage for businesses looking to minimize maintenance costs and downtime.

5. Applications of Double Stage Gear Drives in Industries

Double stage gear drives are utilized in a diverse range of industries, showcasing their versatility and effectiveness:

5.1 Industrial Machinery

In manufacturing, double stage gear drives are commonly used in conveyor systems, milling machines, and robotic arms to provide precise control and reliable torque.

5.2 Automotive Engineering

In the automotive sector, double stage gear drives facilitate efficient power transmission in electric vehicles and hybrid systems, enhancing performance and fuel efficiency.

5.3 Renewable Energy

Wind turbines and solar tracking systems also benefit from double stage gear drives, which optimize the capture of energy by adjusting the angle and position based on environmental conditions.

5.4 Robotics and Automation

Robotic systems rely on the precision and reliability offered by double stage gear drives, allowing for intricate movements and tasks in various applications, from assembly to surgery.

6. Innovations in Gear Drive Technology

The gear drive industry continues to witness significant innovations aimed at improving efficiency and performance. Some of the latest trends include:

6.1 Smart Gear Drives

The integration of IoT technology into gear drives enables real-time monitoring and diagnostics. Smart gear drives can communicate data regarding performance, wear, and operational efficiency, allowing for predictive maintenance.

6.2 Advanced Materials

The development of new materials, such as carbon fiber composites and advanced alloys, enhances the performance and durability of gear drives, making them suitable for increasingly demanding applications.

6.3 3D Printing Technology

3D printing technology offers the potential for rapid prototyping and customization of gear designs. This innovation allows manufacturers to create tailored solutions that meet specific application requirements.

7. Maintenance and Reliability of Gear Drives

Maintaining double stage gear drives is crucial for ensuring long-term reliability and performance. Regular inspection and maintenance activities, such as lubrication and alignment checks, can dramatically extend the lifespan of these systems.

7.1 Importance of Regular Maintenance

Routine maintenance helps detect potential issues early, preventing costly failures. Establishing a maintenance schedule that includes lubrication, inspection, and component replacement is essential for optimal performance.

7.2 Signs of Wear and Tear

Operators should be vigilant for signs of wear, such as unusual noises, vibrations, or decreased performance. Addressing these issues promptly can prevent further damage and ensure the continued reliability of the gear drive.

8. Future Trends in Double Stage Gear Drives

As technology progresses, the future of double stage gear drives looks promising. Key trends shaping their development include:

8.1 Increased Automation

The push for greater automation in various industries will drive demand for more sophisticated gear drive systems that can handle complex tasks with precision and efficiency.

8.2 Sustainability Initiatives

With growing concerns about environmental impact, the focus on energy-efficient gear drives that reduce waste and conserve energy will become increasingly important.

8.3 Enhanced Integration with AI

The integration of artificial intelligence into gear drive systems will enable advanced predictive maintenance, optimizing performance and minimizing downtime.

9. Frequently Asked Questions

9.1 What are double stage gear drives?

Double stage gear drives are mechanical systems that use two sets of gears to reduce speed and increase torque, commonly employed in various applications to enhance efficiency.

9.2 How do double stage gear drives differ from single-stage drives?

Double stage gear drives provide greater torque multiplication and better speed control compared to single-stage drives, making them suitable for more demanding applications.

9.3 What industries utilize double stage gear drives?

Industries such as manufacturing, automotive, renewable energy, and robotics frequently use double stage gear drives due to their efficiency and reliability.

9.4 What maintenance practices are recommended for double stage gear drives?

Regular lubrication, alignment checks, and inspection for wear are crucial maintenance practices to ensure the longevity and performance of double stage gear drives.

9.5 What is the future of double stage gear drives?

The future of double stage gear drives includes advancements in automation, sustainability, and integration with smart technologies, enhancing their capabilities and applications.

10. Conclusion

Double stage gear drives represent a significant advancement in the evolution of electrical systems. Their ability to enhance torque output and provide precise speed control makes them invaluable across various industries. With ongoing innovations and a commitment to efficiency, the future of double stage gear drives holds even more promise. As we continue to explore and develop these technologies, we can expect them to play a crucial role in the transformation of electrical engineering and power transmission systems worldwide.

Related news